How we do it

In a world filled with countless choices, how can we fulfill the need for high-quality living space - a space that truly reflects us, whether surrounded by the tranquility of mountains, captivated by the allure of the coastline, or seamlessly integrated into vibrant urban residential areas?

At EOScale, we have the solution: Modular homes that excel in design and functionality.

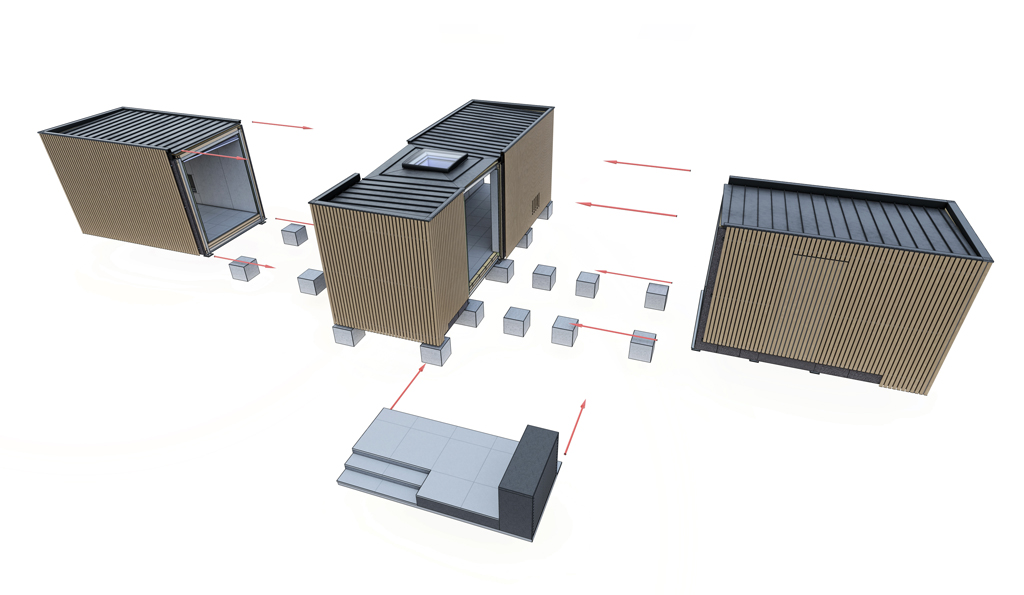

Module Connection

The basic structure of every EOScale home is one module, designed following the golden ratio and adjusted for easy transportation. Each home consists of at least 2 modules, which can be transported individually or together.

At the location, they are assembled with the help of a mobile crane onto a prepared reinforced concrete foundation. The modules are joined horizontally using screws to connect them securely to the foundation. The connectors are the only parts assembled on-site, making the overall assembly process faster and more efficient for both the exterior and interior of the building.

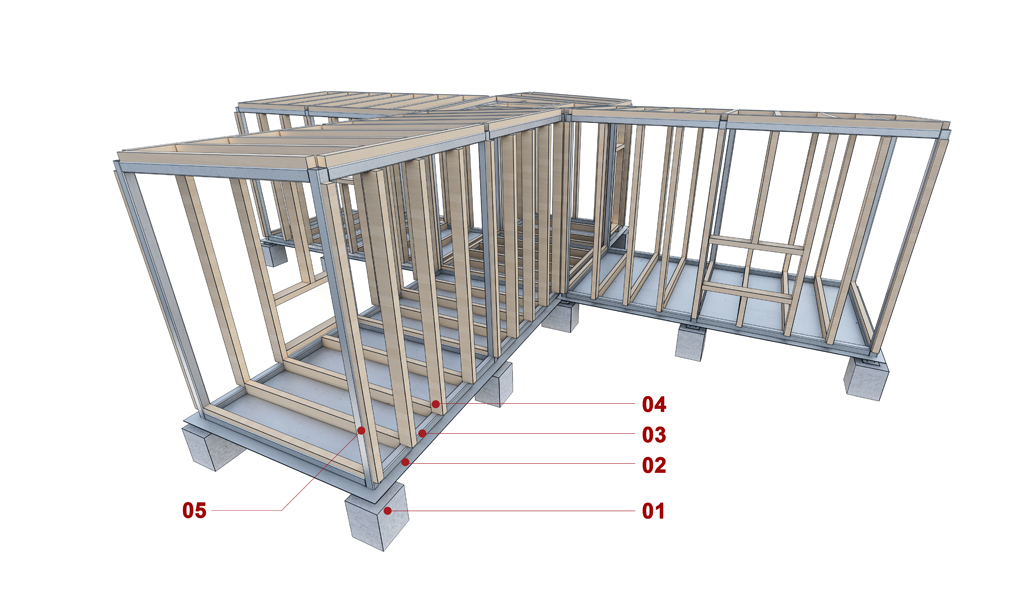

Module Structure

The structural system is a framed steel system composed of box steel profiles combined with coupled steel/wood beams and additional filling made of laminated wooden beams. It sits on reinforced concrete foundations supported by galvanized steel plates. The design meets the current EU standards for stability, resistance to external forces, and earthquakes.

- Reinforced concrete free-standing foundation

- Galvanized steel plate

- Box/steel construction

- Laminated wooden construction

- Coupled wood/steel construction

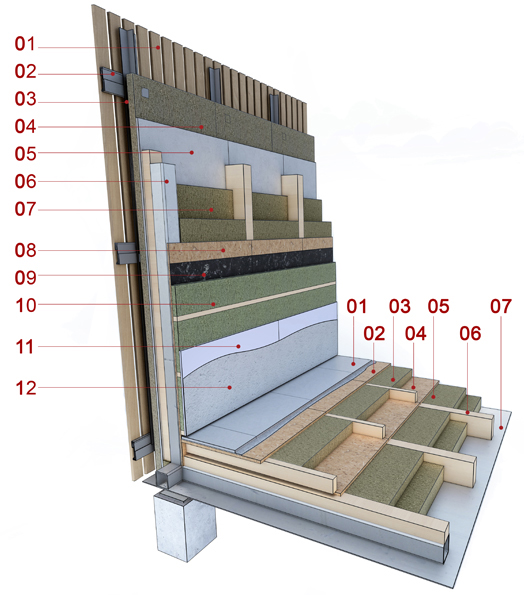

The science behind EOScale homes

All exterior surfaces of EOScale homes are designed and built with a clear purpose: to meet the prescribed and defined requirements of architectural physics. We set out to achieve three main specific goals:

- Low U-value for the surfaces. This goal has been met with a value of 0.12 W/m²K for floor and 0.13 W/m²K for roof and walls, and 0.8 W/m²K for openings.

- Ensure proper vapor flow through the layers, preventing the occurrence of condensation, which we also achieved.

- Ensure thermal stability for the walls and roof during hot weather, which has been achieved through ventilated layers in all external walls and roof structures.

Wall - Floor connection

Wall Structure

from 35 to 40 cm

depends on façade type

- External facade cladding

- Substructure for ventilated facade system

- Ventilated air gap

- Thermal insulation – rock mineral wool

- Vidipan board

- Load-bearing structural system wood/steel

- Thermal insulation - glass wool

- OSB 3 board

- Vapor barrier

- Additional thermal insulation – rock mineral wool

- Gypsum board (drywall)

- Final interior surface finishing

Floor Structure

30,4 cm

- Final finishing of the interior surface

- OSB 3 board

- Thermal insulation – rock mineral wool

- OSB 3 board

- Thermal insulation – rock mineral wool

- Load-bearing structural system wood/steel

- Galvanized steel plate

Wall - Roof connection

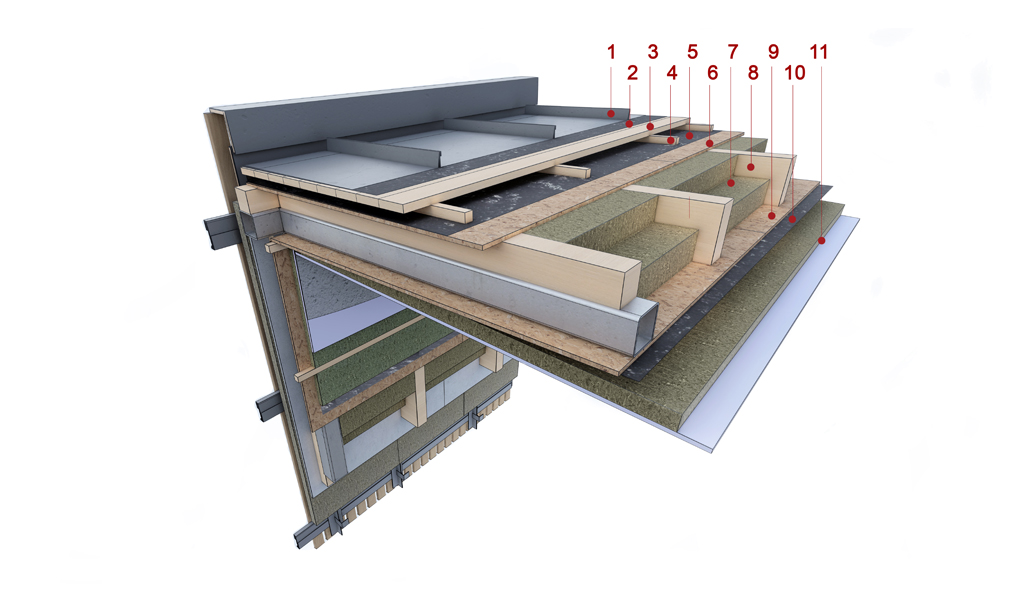

Roof structure

30 cm

- Flat sheet metal - Prefalz

- Waterproofing layer

- Wooden underlayment

- Ventilated air gap

- Vapor-permeable and waterproof membrane

- OSB 3 board

- Thermal insulation - glass wool

- Load-bearing structural system wood/steel

- OSB 3 board

- Vapor barrier

- Suspended ceiling with gypsum board